Multitasking machining on complex components in precision general engineering applications

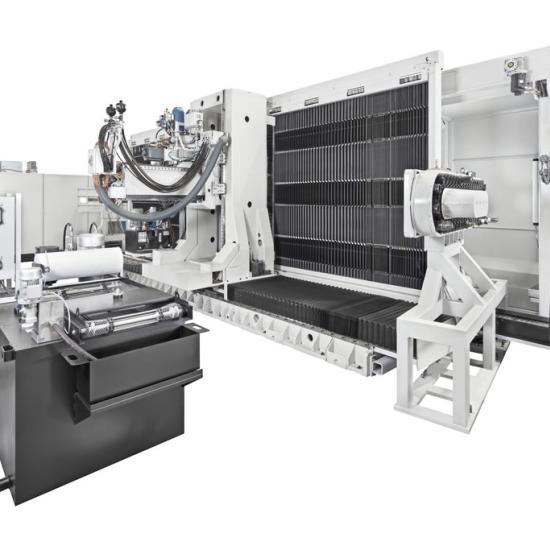

Sachman FRAZER MILLTURN is a medium-size universal horizontal milling machine with moving column for 3/4/5-axis multitasking machining. Equipped with a rotary table for milling and turning operations, FRAZER MILLTURN simplifies production planning by reducing the number of fixtures, tools and set-ups and ensures maximum productivity by limiting idle times.

It is available in two versions: FRAZER BOX, completely enclosed, with a longitudinal stroke ranging from 3 to 5 metres and FRAZER OPEN, with perimeter fence and longitudinal travels of up to 30 metres.

The wide range of configurations available for FRAZER ensure a considerable high degree of application flexibility and allow to cut hourly and operating costs making it the perfect proposal for end-users looking for cutting-edge technology at competitive costs.

Technical features

BOX

- Longitudinal X-Axis 3000-4000-5000 mm

- Vertical Y-Axis 1500-2000 mm

- Transversal Z-Axis 1100 mm

- Turning-milling rotary table dia. 1000 mm, built in the fixed table

- Speed up to 35 m/min

OPEN

- Longitudinal X-Axis 4000-6000-7000 mm +Δ 1500 mm

- Vertical Y-Axis 1500-2000-2500 mm

- Transversal Z-Axis 1100-1300 mm

- Turning-milling rotary table dia. 1000-2000 mm, in both fixed and rototranslating versions

- Speed up to 35 m/min

- Universal milling head with continuous positioning and torque motors - 8000 rpm max. rotation speed - assuring high positioning speed and accuracy

- Wide range of tool magazines available:

- Disk-type with mechanical hand 24 or 30 positions

- Horizontal floor-mounted chain-type 40 or 60 positions

- Vertical chain-type, mounted on column, 40 or 60 positions (for OPEN version only)

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and probing systems