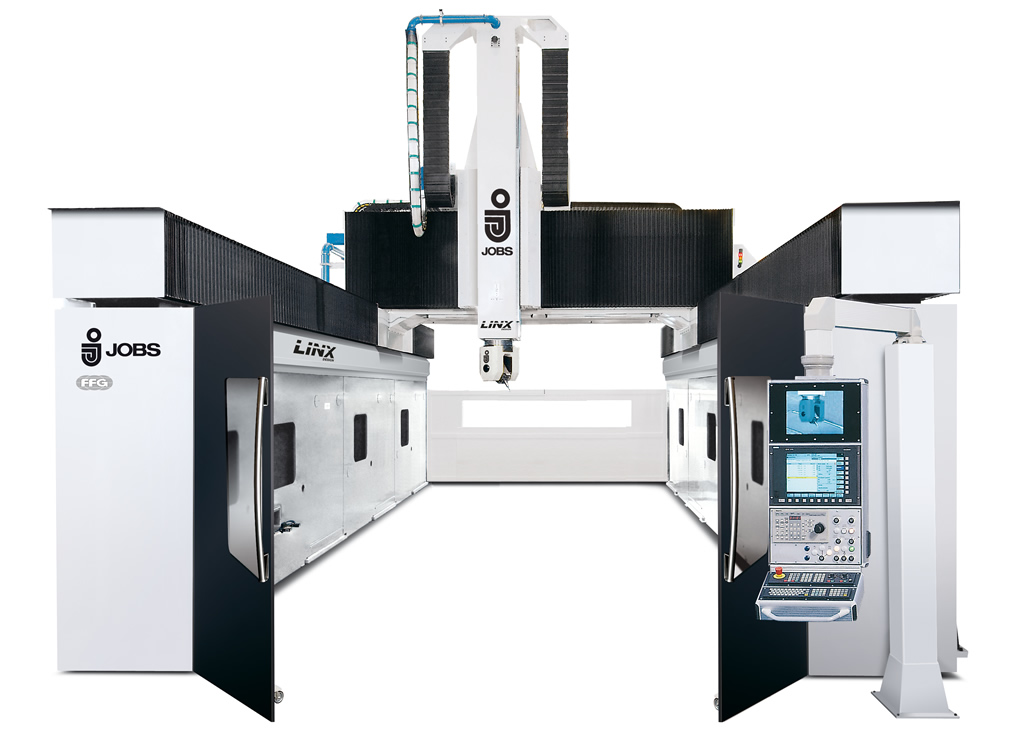

LINX linear motor gantry family: very high-speed 5-axis machining culture

LINX, a very high-performance vertical milling machine, is the first model in the same name family that gained a top-spot position on the market, thanks to its advanced technological content focused on the use of linear motors on middle-large size machines.

The use of these motors on all linear axes, combined with the high-rigidity structures, allows high performances in terms of dynamics, drastically reduces machining times, ensures very high accuracy and finishing quality, guarantees cut-down maintenance due to fewer wearable components, and improves working environment quality for its silent functioning provided by the absence of mechanical transmission.

LINX milling machines feature a modular design based on a system of multifunctional subassemblies allowing wide possibilities of customization in terms of machining applications as well as plant layout. They are equipped with a complete work area enclosure according to the most modern environmental protection and safety regulations.

LINX has been conceived according to JOBS Green Vision, resulting in a significant reduction of power consumption.

Technical features

- X-Axis 2000-4000-6200 mm +Δ 2000 mm

- Y-Axis from 2000 to 6000 mm

- Z-Axis from 900 to 2500 mm

- Speed up to 70 m/min

- Very high acceleration

A wide range of fork-type twist heads for 5-axis machining with the best electrospindles to perfectly fit your application requirements:

- Up to 125 kW for aluminium machining

- Up to 550 Nm for an effective machining of steel and cast-iron

- Performing grease-lubricated 24000 rpm electrospindle, for composite and resin machining

- Spindle cartridges are equipped with a standard interface allowing quick and easy change for maintenance purposes

- Fixed worktable with different loading capacities

- Folding top cover with automatic opening to access work area

- Wide range of tool magazines available:

- Direct chain from 16 to 40 positions

- Single/double chain with double gripper change arm from 48 to 96 positions

- Rack type with large storage capacity for up to 300 tools and possible second change arm for double work-area

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and coding systems, probing systems

- High-efficiency dust suction systems

- High-accuracy countersinking systems with depth dynamic control, with or without integrated suction

- Systems designed for wet or dry (Jobs’ patent) composite machining, as well as wet & dry combined machining, including wastes collection and compacting

- Work area separation into two operating zones for pendulum operation: part machining in one area and loading/unloading in masked time in the other

- Automatic pallet systems

- Remote surveillance systems