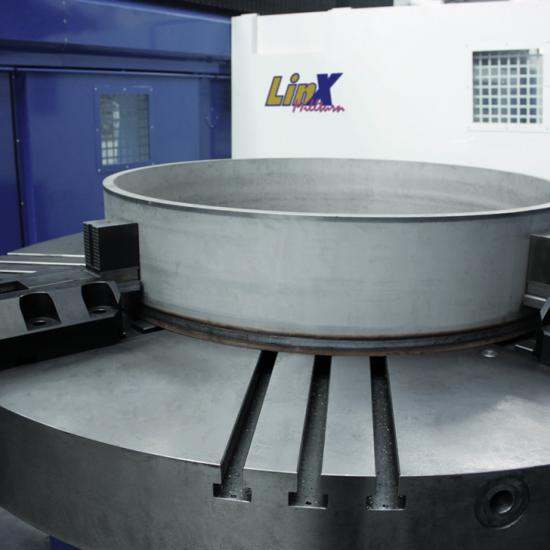

- Turning and milling rotary table with high load capacity

- Flexibility of use on different materials such as aluminium, steel, and cast iron

- Reduced number of machining operations and idle times to optimize productivity

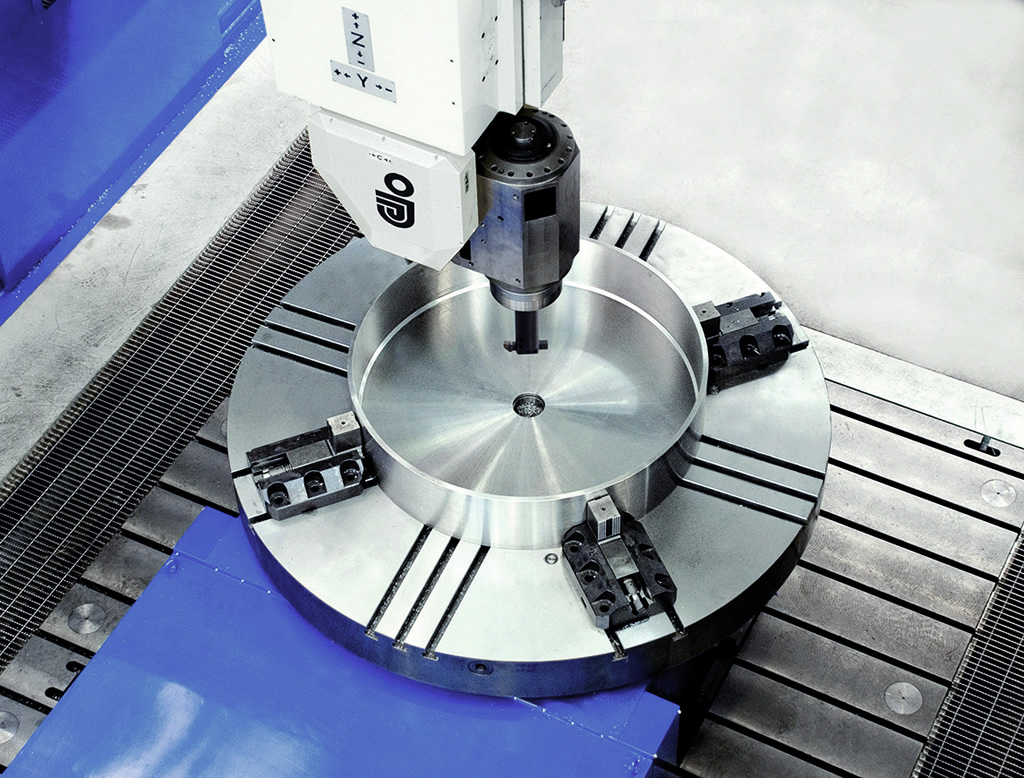

- Maximum accuracy and excellent surface quality of the finished component

Applications

High performance multitasking machining with linear motors

LINX MILLTURN was the first 6-axis vertical milling/turning machine with linear motors and moving crossbeam for very high speed and high-power multi-tasking roughing and finishing operations. The perfect match between linear motors and high rigidity gantry structure guarantees top accuracy performance for excellent finishing quality.

Equipped with a rotary table for milling and turning operations, LINX MILLTURN simplifies production planning by reducing the number of fixtures, tools and set-ups and ensures maximum productivity by limiting idle times.

This machine features a complete reinforced enclosure of work area to enable totally safe turning mode operations.

Technical features

- X-Axis 2000-4000-6200 mm +Δ 2000 mm

- Y-Axis from 2000 to 6000 mm

- Z-Axis from 900 to 2500 mm

- Speed up to 50 m/min

- Very high acceleration

Continuous and/or indexed fork-type twist heads with the best electrospindles to perfectly fit your application requirements:

- Up to 125 kW for aluminium machining

- Up to 550 Nm for an effective machining of steel and cast-iron

- Wide choice of rotary tables for milling and turning operations

- Folding top cover with automatic opening to access work area

- Large range of tool magazines available:

- Direct chain from 16 to 40 positions

- Single/double chain with double gripper change arm from 48 to 96 positions

- Rack type with large storage capacity for up to 300 tools and possible second change arm for double work-area

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and coding systems, probing systems

- Work area separation into two operating zones for pendulum operation: part machining in one area and loading/unloading in masked time in the other

- Automatic pallet systems

- Remote surveillance systems