- Cast-iron structure for maximum stability and rigidity

- Highest accuracy values and top quality of machined parts guaranteed by pressurised scales mounted on the X, Y and Z axes

- High dynamics thanks to large-sized recirculating ball screws with preloaded double nut, combined with digital direct drives and motors

- Excellent accessibility and ease of loading/unloading

Applications

An innovative product at the forefront of technology: speed, accuracy, power in a single solution

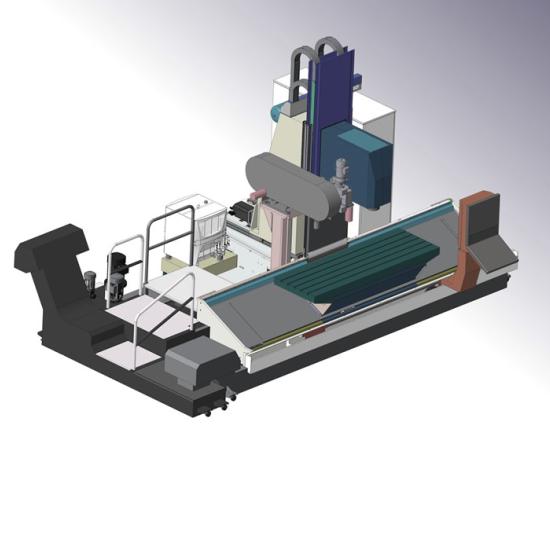

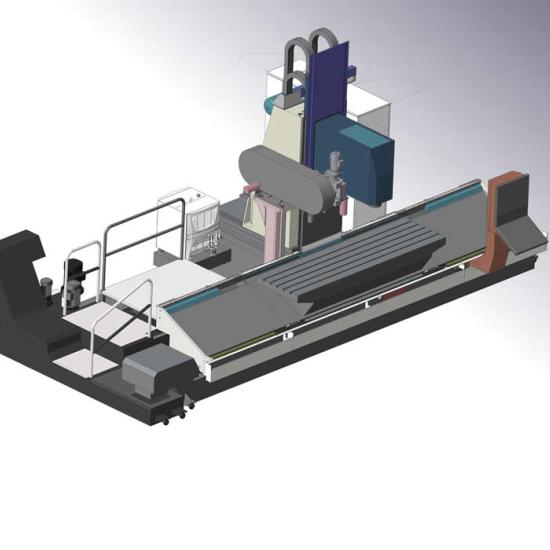

Sigma FLEXI 3 vertical machining centre with moving table belongs to Sigma FLEXI range, designed to maximise performance in the machining of medium to large sized parts in precision engineering, automotive, medical, and aeronautical applications and in the production of moulds and dies.

The possible configurations of the Sigma FLEXI 3 machining centre and the available options allow the machine to be fitted according to the customer's specific production requirements.

The all-cast-iron structure maximize the rigidity features of Sigma FLEXI 3 under conditions of maximum use of the motor spindle power and torque.

Equipped with the latest generation CNCs enhancing the accuracy and speed of machining, Sigma FLEXI 3 features a highly ergonomic operator panel, positioned on a sliding front structure.

Machine full enclosure is conceived according to the most innovative industrial design criteria and integrates various functions: ergonomics, easy access to the work area, wide visibility of the operating area during machining, easy loading/unloading of workpieces, containment of fumes and machining residues, ease of use and maintenance.

Sigma FLEXI 3 is available in three models according to X-axis stroke: S, L, XL

Technical features

- FLEXI 3S: X 1250, Y 800, Z 715 mm

- FLEXI 3L: X 2100, Y 800, Z 715 mm

- FLEXI 3XL: X 3000, Y 800, Z 715 mm

- Axis speed up to 50 m/min

- Motor spindle driven by a synchronous motor providing a rotation speed of 15000 rpm

- Optional motor spindle with 18000 rpm

- Tool magazine with 40 o 60 positions

- Tool pre-setting unit

- Workpiece measuring probe

- Cooling systems

- Rotary tables

- Kit Industry 4.0