The best cost-performance ratio resulting from our proven expertise in 5-axis high-speed machining

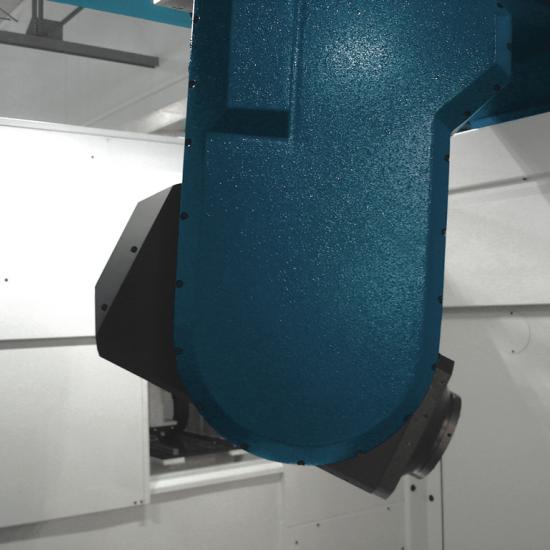

Rambaudi RC270 is a 5-axis overhead gantry milling centre with high dynamic performance and removal capacity.

High structural rigidity and double guides along each X-axis ensure the best possible positioning accuracy to guarantee consistently high machining quality.

Rambaudi RC270 integrates design and functional solutions specifically aimed at semi-finishing and finishing operations on steel and cast-iron moulds and dies and complete machining of aluminium alloy parts, both for the aerospace and the mould and die industry, where it represents the ideal solution for try-outs alongside moulding lines.

Rambaudi RC270 is fitted with a complete enclosure allowing an efficient chip containment, high accessibility for part loading/unloading, ergonomics, and safety for the operator.

Technical features

- X-Axis 2200-3000-4000 mm +Δ 2000 mm

- Y-Axis 2700 mm

- Z-Axis 1250 mm

- Speed up to 40 m/min

Fork-type twist heads equipped with the best electrospindles to perfectly meet your 5-axis machining requirements:

- Up to 170 Nm

- Double offset to ensure the best approach to the workpiece and maximum penetration while increasing the operating volume

- Fixed worktables with different loading capacities

- Folding top cover with automatic opening to access work area

- Tool magazines available:

- Rotary sliding chain type from 24 to 42 positions

- Rack type with large storage capacity for up to 300 tools

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and coding systems, probing systems

- Automatic pallet systems

- Remote surveillance systems for unmanned operation