The excellence in high power milling technology on tough materials

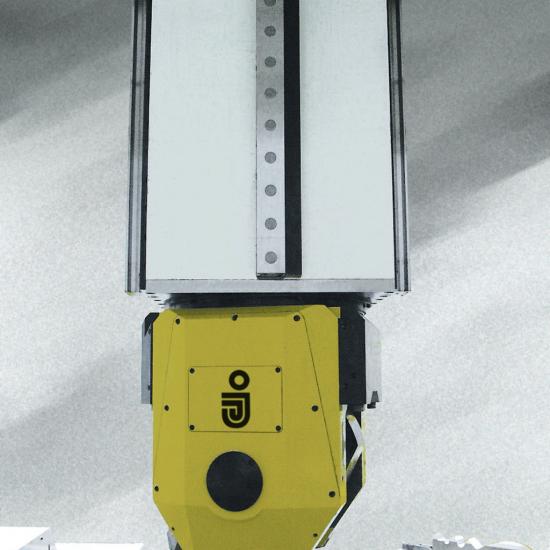

JOMAX 265 features a medium to large size mobile gantry architecture for 3/3+2/4/5-axis machining with very high stock removal rates and excellent dynamic performance.

In addition to the X,Y & Z axes, a NC controlled 4th axis (W) expands machining capability and provides exceptional rigidity for particularly severe cutting conditions.

X-axis guides under floor level ensure that very long workpieces can be loaded from the front and from the side while guaranteeing ergonomics and easy access to the work area.

JOMAX 265 milling centres ensure exceptional versatility of use, allowing the widest possible customisation and automation according to specific application needs, thus enhancing the competitiveness of end-users for high-power machining in precision general mechanics, energy and heavy mechanics, large size moulds & dies and heavy machining of large structural parts in tough materials.

Technical features

- X-Axis 6500-8000-9500 mm +Δ 1500 mm

- Y-Axis from 3000 to 8000 mm

- Z-Axis from 1250 to 2500 mm

- W-Axis positioning option - stroke up to 2500 mm – NC fully programmable crossbeam vertical movement

- Speed up to 28 m/min

A wide range of heads and spindles to best meet your machining requirements:

- Up to 3300 Nm for heavy-duty machining, specifically on tough materials

- Mechanical vertical/horizontal/fork-type twist heads and customized

- Electrospindle fork-type twist heads

- Automatic head changing system (BUSS)

- Cast-iron worktables, independent from the machine structure, with different loading capacities

- Several tool magazines available:

- Chain-type on board machine with double gripper change arm from 40 to 80 positions

- Rack type with large storage capacity for up to 300 tools and possible second change arm for double work-area

- Tool cooling systems external and/or through tool and chip evacuation systems

- Tool measuring and coding systems, probing systems

- Work area separation into two operating zones for pendulum operation: part machining in one area and loading/unloading in masked time in the other

- Automatic pallet systems